How do the current-limiting and breaking performance of a frame universal circuit breaker ensure the safety of downstream equipment?

Publish Time: 2025-12-23

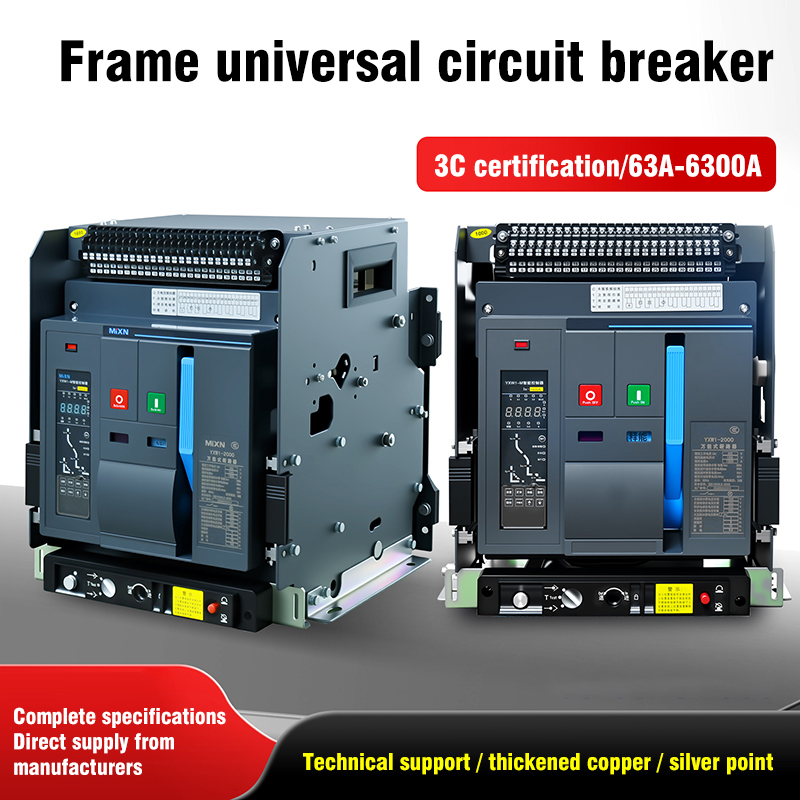

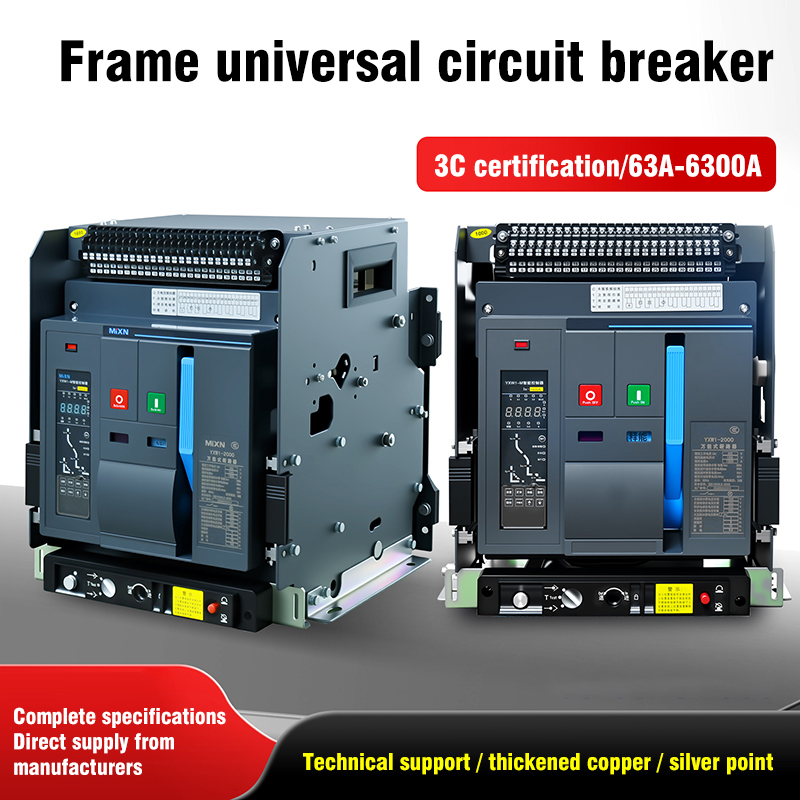

In modern low-voltage power distribution systems, the frame universal circuit breaker, as a core protection component, bears the important responsibility of distributing power, isolating faults, and ensuring the safety of personnel and equipment. Its current-limiting and breaking performance directly determine whether the entire power distribution network can quickly and reliably interrupt fault currents in abnormal operating conditions such as short circuits, overloads, undervoltage, or grounding, thereby effectively protecting downstream electrical equipment from damage.1. Precision Forged Copper Terminals: Laying the Foundation for High ConductivityThe terminals of a frame universal circuit breaker are key components connecting the main circuit, and their conductivity directly affects overall operating efficiency and temperature rise control. High-purity copper terminals manufactured using precision forging processes not only use sufficient material and have a reasonable cross-sectional area, but also have a dense internal structure, significantly reducing contact resistance. This design effectively reduces energy loss and heat generation during energization, improving long-term operational stability. Meanwhile, under high current surges, high-quality copper can withstand higher thermal stress, preventing insulation aging or contact welding due to localized overheating, thus providing a stable and reliable power supply interface for downstream equipment.2. LCD Intelligent Display Screen: Real-time Monitoring, Precise JudgmentModern frame-type circuit breakers are generally equipped with LCD displays that can show key parameters such as current, voltage, power factor, fault type, and operating time in real time. This function allows maintenance personnel to intuitively grasp the equipment's operating status without additional instruments, providing timely warnings before anomalies occur or quickly locating the cause after a fault. For example, when the system shows a slight overload trend, the display screen can provide an early warning, facilitating load adjustment measures; if a short circuit occurs, the screen records the peak fault current and breaking time, providing data support for subsequent analysis. This "visible" protection mechanism greatly improves the intelligence level and response speed of the power distribution system, indirectly enhancing the safety protection capabilities of downstream equipment.3. High-Performance Contact System: Ensuring Reliable Breaking Under Extreme ConditionsThe contact system is the core component of a circuit breaker for realizing circuit switching, and its design directly determines the breaking capacity. Frame universal circuit breakers typically employ double- or multi-break structures made of high-arc-resistance materials such as silver alloys or silver cadmium oxide. Combined with an optimized arc-extinguishing chamber design, they can elongate, cool, and extinguish the arc within milliseconds. Especially in extreme cases where short-circuit currents reach tens of kiloamperes, the contact system must withstand enormous electrodynamic forces and thermal shocks without sticking or burning. Through the coordinated action of precise mechanical linkages and electromagnetic tripping devices, the circuit breaker can rapidly disconnect the circuit when the current first crosses zero, effectively limiting the peak value of the fault current and significantly reducing the risk of damage to downstream equipment such as cables, transformers, and motors from short-circuit energy.4. High Conductivity and Anti-Electrical Repulsion Design: Enhancing Electrical StabilityWhen large currents, especially short-circuit currents, pass through, strong electrical repulsion forces are generated between conductors, which may lead to internal structural deformation or even mechanical failure. Therefore, high-end frame circuit breakers use high-conductivity materials and optimized layouts in the conductive circuit design to reduce circuit inductance and mitigate electrodynamic effects. Meanwhile, key connection points are reinforced with thickened cross-sections and added support points to enhance mechanical strength, ensuring structural integrity and electrical continuity even under extreme operating conditions. This impact-resistant, low-repulsion design not only improves the reliability of the circuit breaker itself but also reduces secondary faults caused by arc reignition or disconnection failure, creating a more robust safety barrier for downstream loads.

5. Flame-retardant casing and thickened steel frame: Enhancing physical and fire safetySafety is not only reflected in electrical performance but also in structural protection. The casing of frame-type circuit breakers is generally made of high-performance flame-retardant resin material with a UL94 V-0 flame-retardant rating. In the event of a severe internal arc fault causing high temperatures, the casing can quickly self-extinguish, preventing the flame from spreading to adjacent equipment or building structures. Furthermore, the internal frame is made of thickened cold-rolled steel plate, possessing excellent impact, vibration, and corrosion resistance, enabling long-term stable operation even in high-humidity, high-salt-spray, or strong-vibration environments such as subways and ports. This comprehensive structural design physically eliminates the risk of protection failure due to casing cracking or support deformation. 6. Wide Range of Applicable Scenarios: Verifying Comprehensive Protection EffectivenessThanks to the aforementioned multiple technological safeguards, frame universal circuit breakers have been widely applied in critical locations such as highway tunnel lighting systems, subway traction substations, large factory workshop distribution cabinets, port shore power facilities, and main power lines in high-rise office buildings. In these scenarios with extremely high requirements for power supply continuity and safety, circuit breakers must not only cope with daily load fluctuations but also operate with "zero error" during sudden short circuits. Actual operating data shows that frame circuit breakers equipped with advanced current limiting and breaking technologies can limit fault current to below 50% of the original expected value and complete breaking within 10–20 milliseconds, effectively preventing cascading accidents such as cable insulation breakdown, motor winding burnout, and PLC control system failure, truly achieving the protection goal of "reliable upstream disconnection and downstream safety."